Building Envelopes

Building envelopes are the bread and butter of our research, with a major focus on developing enclosures that are cost-effective, durable, and highly energy efficient. CCHRC tests and develops a wide variety of building systems for various regions, from the cold dry climate of Interior Alaska to the wet, windy communities of the Bering Sea coast.

Building envelopes must be thermally efficient as well as moisture safe to hold up over time in the north. They also need to be tailored to the location, as different materials are available on the road system than in a remote, fly-in village.

CCHRC continually engages with industry partners to develop the most cost-effective building envelopes possible. These are tested with a combination of computer modeling and physical testing in the Mobile Test Lab, where we build a variety of wall systems and simulate typical home conditions to monitor their performance over the changing seasons.

Used in over five tests since 2005, the Mobile Test Lab has nine wall bays that allow us to test various building techniques. Each one is outfitted with different combinations of interior insulation, vapor barriers, and exterior insulation and contains sensors recording temperature, wood moisture content, relative humidity, and heat flux through the wall.

With the push to make homes more energy efficient, it is important to understand how new construction and retrofit techniques affect the wall’s ability to handle moisture. The Mobile Test Lab seeks out the most cost-effective ways to retrofit while protecting the durability of the wall.

Check out our different wall designs here.

Learn about the Mobile Test Lab studies below:

The effect of the double vapor barrier: This study examined how adding various amounts of rigid foam to the exterior of the wall affected the wall’s ability to breathe and what the ideal amount of insulation would be to balance cost and durability.

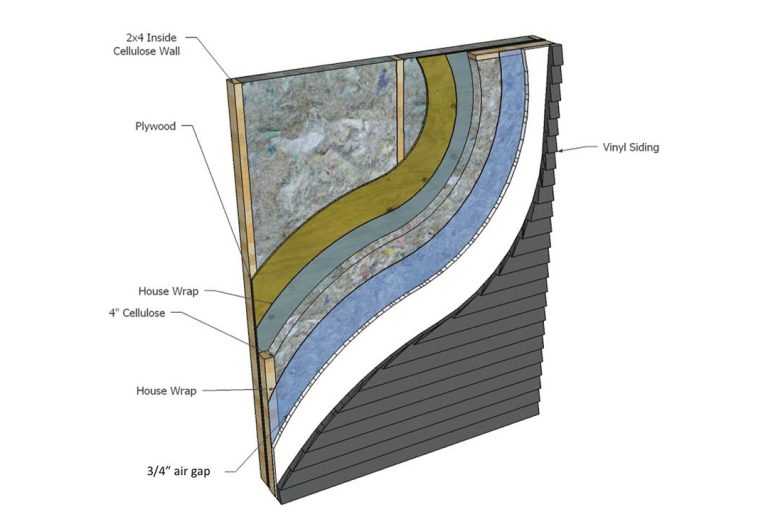

Vapor-open exterior retrofits: This project looked at vapor-permeable alternatives, such as cellulose, to using exterior foam for retrofits. The walls not only reduced cost but also improved moisture performance.

Open-cell spray foam: This study looked at a variety of retrofit techniques, including open-cell spray foam, to see how walls managed moisture.

Related Resources

| Title | Resource Link |

|---|---|

| Arctic Wall Report | |

| Arctic Wall Snapshot | |

| Cellulose Insulation Snapshot | |

| Durable Envelopes Report | |

| Installing a Vapor Barrier | |

| REMOTE Manual | |

| Vacuum Insulated Panels Report |